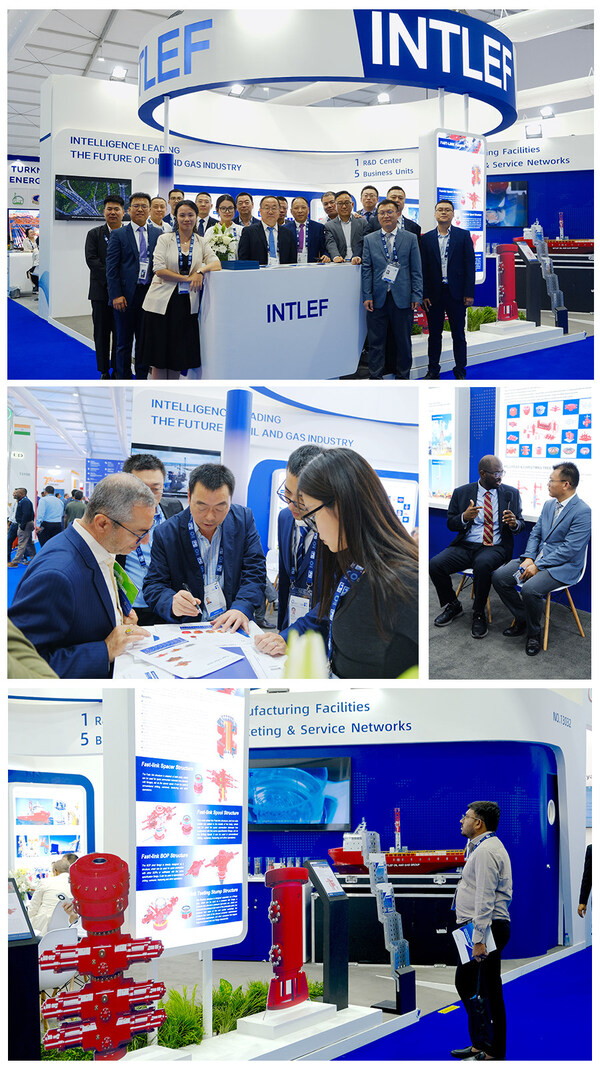

INTLEF Shines at ADIPEC 2024

2024-11-14 INTLEF Oil and Gas Group HaiPress

SHANGHAI,Nov. 13,2024 -- On Nov. 4,2024,the highly anticipatedADIPEC 2024 Exhibition and Conference opened grandly in Abu Dhabi,the capital of the UEA. It has attracted over 2,000 exhibitors and industry experts from around the world to explore the future of energy development.

Since the establishment of INTLEF Oil & Gas Group in 2019,we have been committed to providing high-quality,intelligent drilling equipment and solutions to global clients.

Advancing the Digital Transformation of the Oil and Gas Industry

One of the highlights of INTLEF's exhibit was the AI-EMS energy storage electric workover rig,specially developed to align with the future trends of intelligent,efficient,and low-carbon technology in drilling and workover equipment.

Compared to traditional workover rigs,the unique AI-EMS intelligent integrated energy management system reduces the rig's installed power demand by 40%. It achieves a 30% fuel saving under conventional diesel power generation conditions.

Additionally,the rig system integrates advanced multi-power source management capabilities,allowing it to use multiple power sources,including high- and low-voltage well site power,conventional diesel generators,energy storage batteries,and even photovoltaic power,enabling a truly green workover operation with an overall carbon reduction potential of 60-80%. The display attracted considerable customer attention and drew an interview from IADC magazine.

Furthermore,the 409 exploration vessel model equipped with INTLEF's offshore drilling package attracted many visitors. This offshore drilling package is China's first fully independently developed and domestically produced intelligent control marine exploration drilling system,capable of supporting engineering surveys,oil and gas exploration,geological sampling,rope coring,standard penetration,dynamic penetration,static penetration and so on.

Launch of Patented New Product

The Quick-Connect Flange developed in response to drilling site requirements,was also prominently featured. Designed for rapid connections between various high-pressure,large-diameter API 6A standard flanges in the oil and gas drilling industry,it can be applied to flanges connections in other industries as well.

Compared to conventional bolt connections,the Quick-Connect Flange reduces operation time by 75-90%,decreases labour intensity by 95%,and saves drilling costs during the installation and removal of wellhead and BOP flanges.

The tool-free operation eliminates the need for torque wrenches,impact wrenches,or hammers,simplifying and enhancing safety,especially for elevated drilling operations. Hydraulic operation ensures uniform gasket stress,delivering better sealing performance and safety.

During the exhibition,we welcomed hundreds of visitors. Numerous new clients expressed preliminary cooperation intentions and were invited to visit our facility for further inspection and discussions.

In the future,INTLEF Group will continue to stay at the forefront of the industry,accelerating the transformation of intelligent,green,and low-carbon cutting-edge technologies into practical innovations,and working alongside global clients to achieve a bright future in energy development.

Contact Information.

Tel: 86-021-62210991

Email:sales@intlef.com

Website:http://en.intlef.com

About INTLEF

INTLEF Oil and Gas Group Co.,Ltd is an international company specialising in petroleum equipment R & D,manufacturing,operation and maintenance,EOR services,oilfield goods international trading and EPC projects.