Vacuum Molecular Pump

2022-09-22

The air filter plays an important role in the air compressor system. It can filter out dust particles in the air to protect the compressor host, reduce wear and prolong its service life.

For the air environment with chemical pollution, Sullair recommends the use of chemical air filters. While filtering out dust particles in the air, it absorbs various harmful gases in the air, ensuring the lubrication effect and reducing the possibility of the compressor being corroded. . Sullair air filter has the advantages of high filtration efficiency, low flow resistance, long-term continuous use without maintenance, and is trustworthy. Air filtration method - inertial type Because the density of impurities is higher than that of air, when the impurities rotate with the air or turn sharply, the centrifugal inertial force can separate the impurities from the airflow. Filtration consumes energy, and the resistance of filtration directly affects the exhaust volume of the machine, that is, the operating efficiency of the air compressor.

The company's air filtration system takes into account the energy consumption of filtration and the cost of filtration itself.

The initial resistance of the traditional air filter is 2000Pa, and the Sullair Optimalair 1000Pa reduces the pressure loss of the water column by 1000Pa, which is equivalent to increasing the air output of the compressor by 1%.

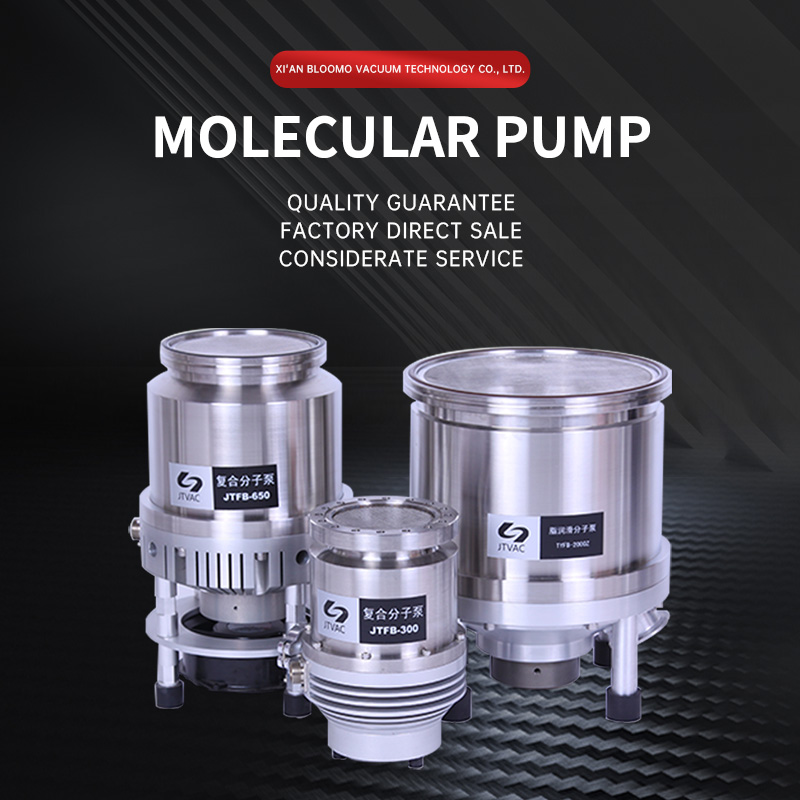

The compound molecular pump has no selectivity and memory effect on the pumped gas. Due to the high compression ratio of the gas with large molecular weight, the pump can obtain clean high vacuum and ultra-high vacuum without cold traps and oil baffles. . It is widely used in various fields of vacuum technology such as photovoltaic, lighting, aerospace, semiconductor, energy, military, laser, home appliances, materials, and automobiles.

JT series air-cooled composite molecular pump and JT series composite molecular pump are composed of turbo molecular pump and disc traction pump. It has the characteristics of high pumping speed and high compression ratio when the molecular flow of turbo molecular pump is high, and the pumping speed when the traction pump is high pressure. The characteristics of large and high compression ratio expand the application range of molecular pumps.

The impeller of JT series grease lubricated molecular pump adopts the first variable-section blade teeth in China, and the bearing adopts grease lubricated ceramic precision bearing, which realizes the installation of the pump body at any angle and a clean and oil-free high vacuum environment with higher reliability.

The impeller of the JTFB-3600 turbomolecular pump adopts the first variable-section blade teeth in China, which enhances the strength of the blade, reduces the weight of the rotor, shortens the startup time, reduces the mechanical loss, and increases the service life.

Xi'an Borusco Vacuum Technology Co., Ltd. was established on December 26, 2017 with a registered capital of 8.6 million yuan. It is located in Xi'an High-tech Industrial Park, the ancient capital of China. It is a company specializing in various domestic and foreign vacuum pumps, molecular pumps, vacuum accessories, vacuum measurement, leak detection equipment, vacuum seals and vacuum pump oil, vacuum exhaust tables, and space environment simulation devices; it integrates vacuum equipment leak detection, vacuum system A high-tech industrial company integrating design, processing, sales, technical after-sales, and maintenance services.

The company mainly produces 600-1600L compound type; 3600L turbine type; 300L, 650L, 1300L, 2000L grease lubrication and other ultra-high vacuum acquisition equipment - molecular pumps, ultra-high vacuum baffle valves of various specifications, ultra-high vacuum units, etc. The company's products are constantly innovating and introducing new products, which are at an excellent level among similar products in China.

The company's related molecular pump products can obtain clean high vacuum and ultra-high vacuum, which are widely used in various fields of vacuum technology such as photovoltaic, lighting, aerospace, semiconductor, energy, military, laser, home appliances, materials, and automobiles. Borusco Vacuum Mainly produces 600, 1200, 1600 L compound type; 3600L turbine type; 300L, 650L, 1300L, 2000L grease lubrication and other ultra-high vacuum obtaining equipment---molecular pump, various specifications of ultra-high vacuum flapper valve and ultra-high vacuum unit , Molecular pump control power supply, etc. The company's products are constantly innovating, ranking the leading level among similar products in China. Customers are located in various regions of China, and the application of molecular pumps in South Korea, Japan, the United States, Iran, India, Taiwan and other countries and regions is also expanding.

Tian Lei

sxblskzhenkong@163.com