Powder Metallurgy Products

2022-10-20

Powder metallurgy uses.

1, powder metallurgy technology can maximize the reduction of alloy composition bias aggregation, eliminate coarse, uneven forging arrangements. In the preparation of high performance rare-earth permanent magnetic materials, rare-earth hydrogen storage materials, rare-earth light-emitting materials, rare-earth catalysts, high-temperature superconducting materials, new metal materials such as Al-Li alloy, heat-resistant Al alloy, superalloys, powder corrosion-resistant stainless steel, powder high-speed steel, intermetallic compounds high-temperature construction materials, etc.) has a major effect.

2, can prepare amorphous, microcrystalline, quasi-crystalline, nanocrystalline and superfull solid solution and a series of high functional non-equilibrium materials, these materials have excellent electrical, magnetic, optical and mechanical properties.

3, can easily complete a variety of types of composite, give full play to the respective characteristics of each group of elemental materials, is a low-cost production of high performance metal-based and ceramic composite material skills.

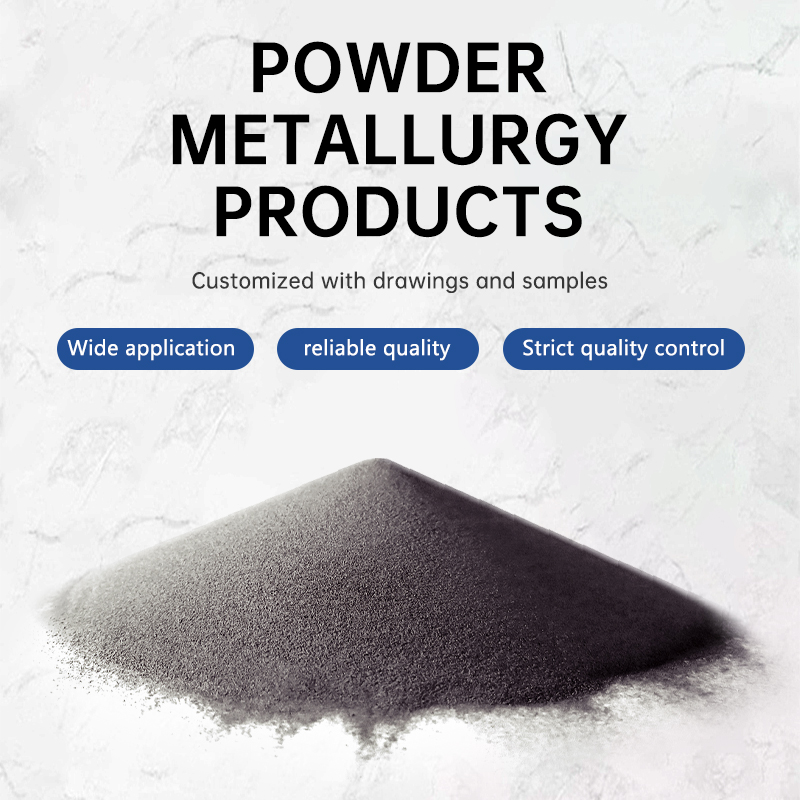

4、It can produce materials and finished products with special structure and function that cannot be produced by ordinary melting method, such as new porous biological materials, porous separation film materials, high functional structural ceramic abrasives and functional ceramic materials, etc.

5、Can complete the near net shape and automated batch production, then, can be useful to reduce the production of capital and energy consumption.

6、It can make full use of ore, tailings, steel sludge, rolled steel scales and recycled scrap metal as materials, which is a new skill that can be useful for material regeneration and comprehensive utilization.

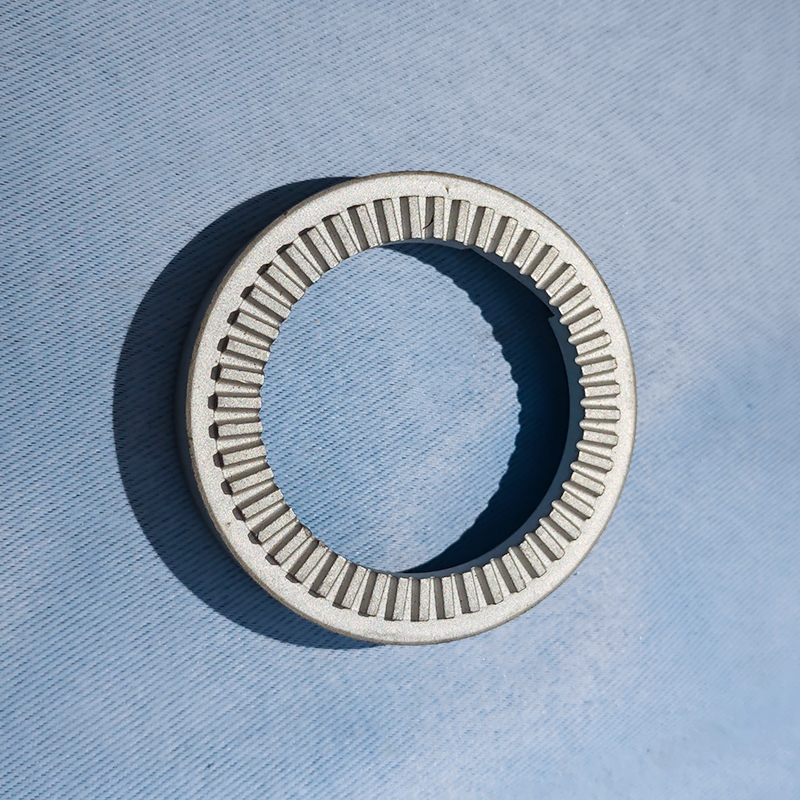

Powder metallurgy has a unique chemical composition and mechanical and physical properties that cannot be obtained by traditional fusion casting methods. Using powder metallurgy technology, porous, semi-dense or fully dense materials and products such as oiled bearings, gears, cams, guide rods, tools, etc. can be made directly as a less cutting-free process. Powder metallurgy technology can minimize alloy composition bias aggregation and eliminate coarse and uneven casting organization.

It has an important role in preparing high-performance rare-earth permanent magnet materials, rare-earth hydrogen storage materials, rare-earth luminescent materials, rare-earth catalysts, high-temperature superconducting materials, and new metal materials (such as Al-Li alloys, heat-resistant Al alloys, superalloys, powdered corrosion-resistant stainless steel, powdered high-speed steel, and intermetallic compound high-temperature structural materials). A series of high-performance non-equilibrium materials such as amorphous, microcrystalline, quasi-crystalline, nanocrystalline and supersaturated solid solutions can be prepared, which have excellent electrical, magnetic, optical and mechanical properties. It is a process technology to produce high-performance metal-based and ceramic composites at low cost, as it can easily realize multiple types of composites and give full play to the respective characteristics of each component material. It is possible to produce materials and products with special structures and properties that cannot be produced by ordinary melting methods, such as new porous biological materials, porous separation membrane materials, high-performance structural ceramic abrasives and functional ceramic materials. It is possible to realize near-net-shape and automated mass production, thus, the resource and energy consumption of production can be effectively reduced. It can make full use of ore, tailings, steelmaking sludge, rolling steel scales, and recycling scrap metal as raw materials, which is a new technology that can effectively carry out material regeneration and comprehensive utilization. Many of our common machining tools, hardware grinding tools, are manufactured by powder metallurgy technology. Production of powder. The production process of powder includes the steps of powder making, powder mixing, etc.

Shangnan County Tianyuan New Energy Equipment Manufacturing Co.

In order to meet the needs of the market and technological innovation, Tianyuan has introduced professional technicians and management personnel from the south to reserve energy for the development and growth of the company and to build up strength to meet greater challenges. Tianyuan company has passed 9001 quality system certification, IATF16949 automotive industry quality management system certification, ccc compulsory product certification, and won the honorary title of entrepreneurial demonstration enterprise and Shaanxi AAA grade credit unit, Shaanxi private science and technology enterprises, etc.

1. The company has its own stainless steel raw material processing plant, the same quality price has a strong competitive advantage so that each guest get the maximum benefit.

2. The company always uphold: quality first, service first guidelines, from raw materials into the factory inspection, to the process of each process inspection, out of the warehouse packaging inspection layer by layer.

3. We have passed ISO9001 certification, IFTA

16949 international automotive industry certification, to obtain quality system certification.

4. The company has more than 95% of fully automatic production lines, with a monthly production capacity of 200 tons, and the production capacity is still being adjusted and expanded to meet the challenges of the market at any time.

Sun Wen

429687231@qq.com

snsdc@126.com